Part of what makes K2S an industry leader is the constant strive to make a better product.

We follow up with customers and encourage product feedback. We then take that feedback and see if there is room to make our products better. This process is a long and involved process that we've honed over the years at our head office. Feedback is what we use as a starting point for product improvements that focus on the enhancement of operation and performance which simultaneously takes into account eco-friendly considerations.

Performance between the gas and carbon lamp heating systems show that there is no significant difference between the output of both systems when considering the cooking teppan temperature over the same period of heating time.

However, one significant difference is that the digital temperature control makes it very easy to set the desired temperature whereas the gas teppan requires constant adjustment of high and low gas input in order to maintain the same cooking temperature.

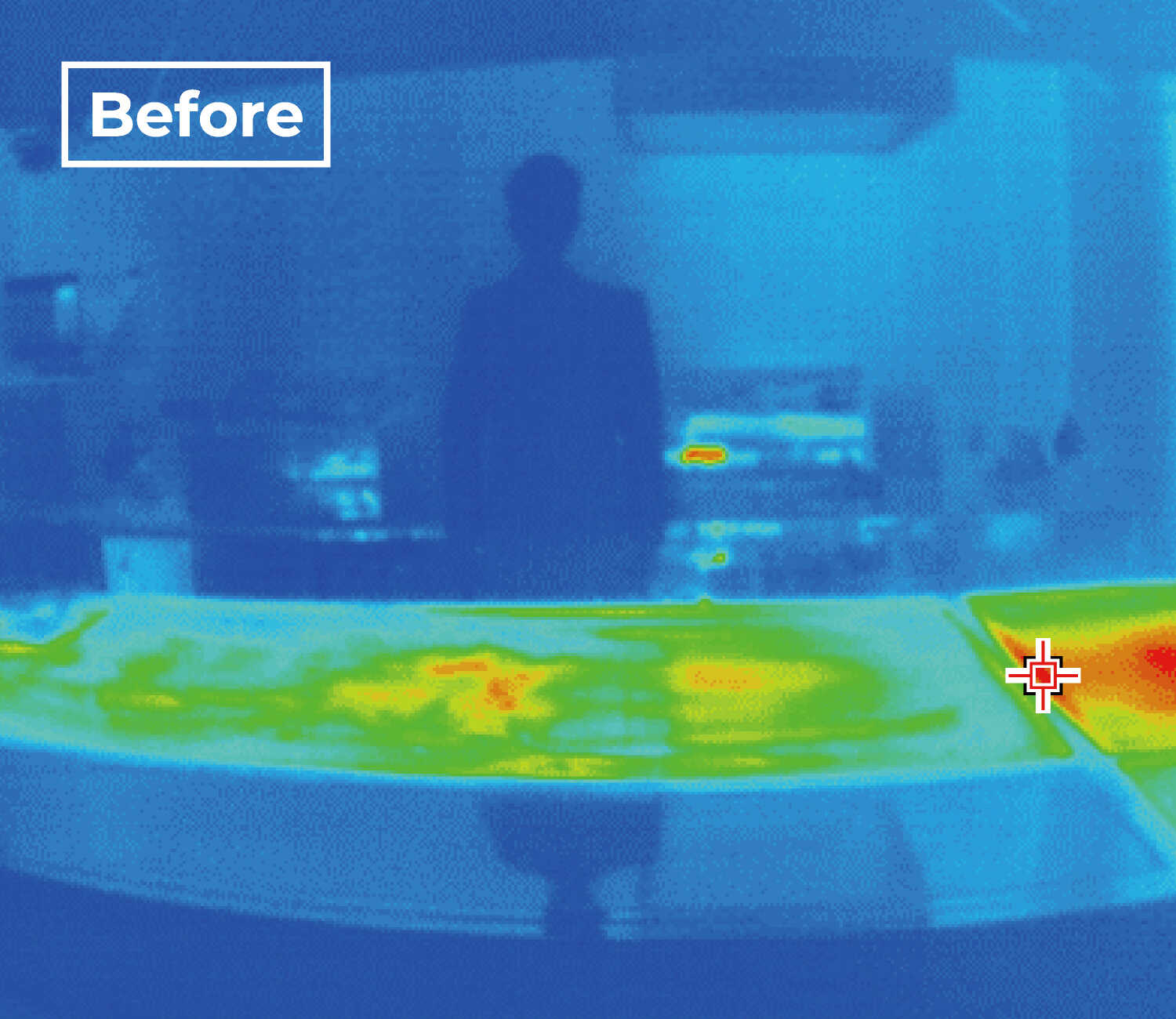

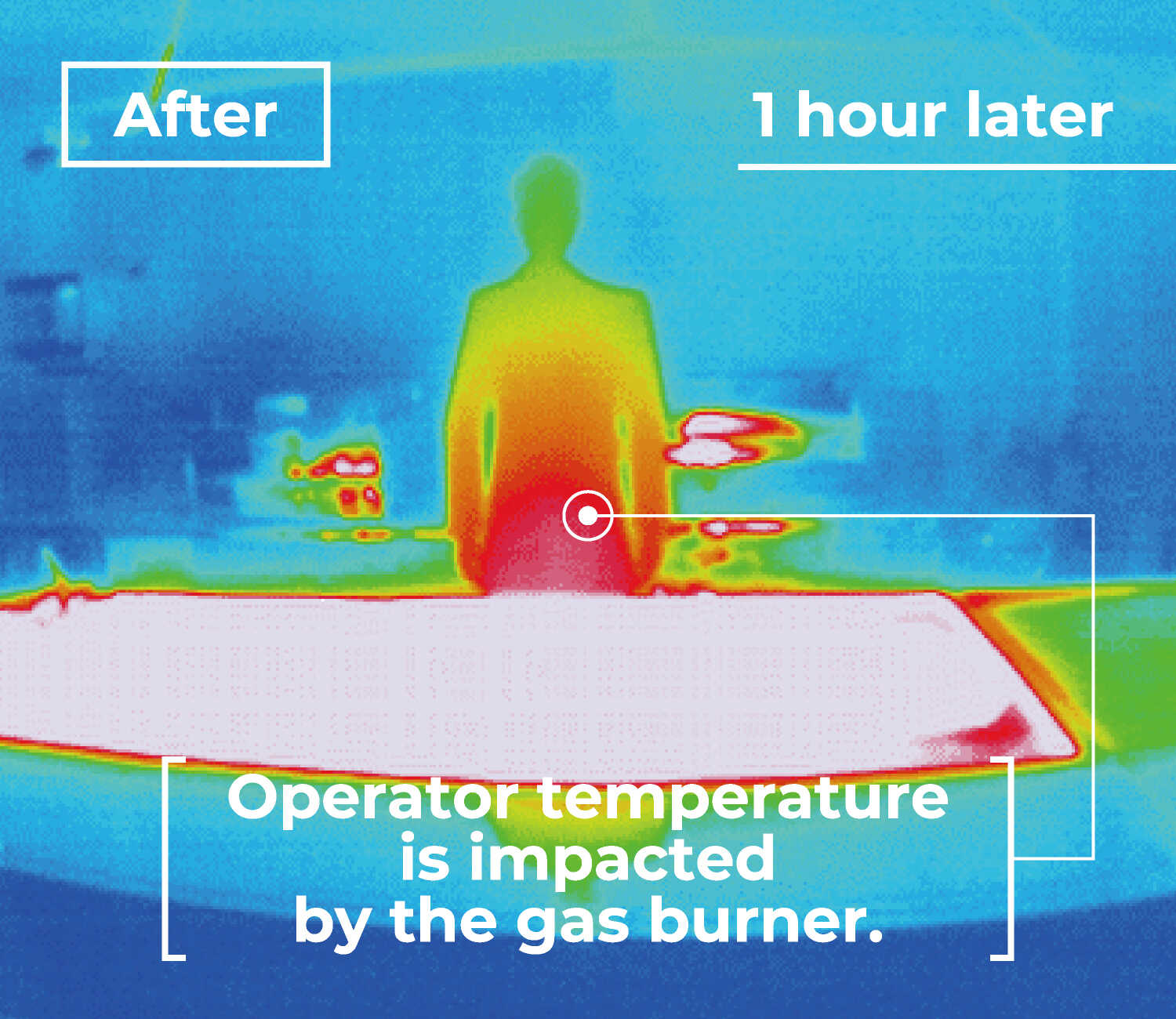

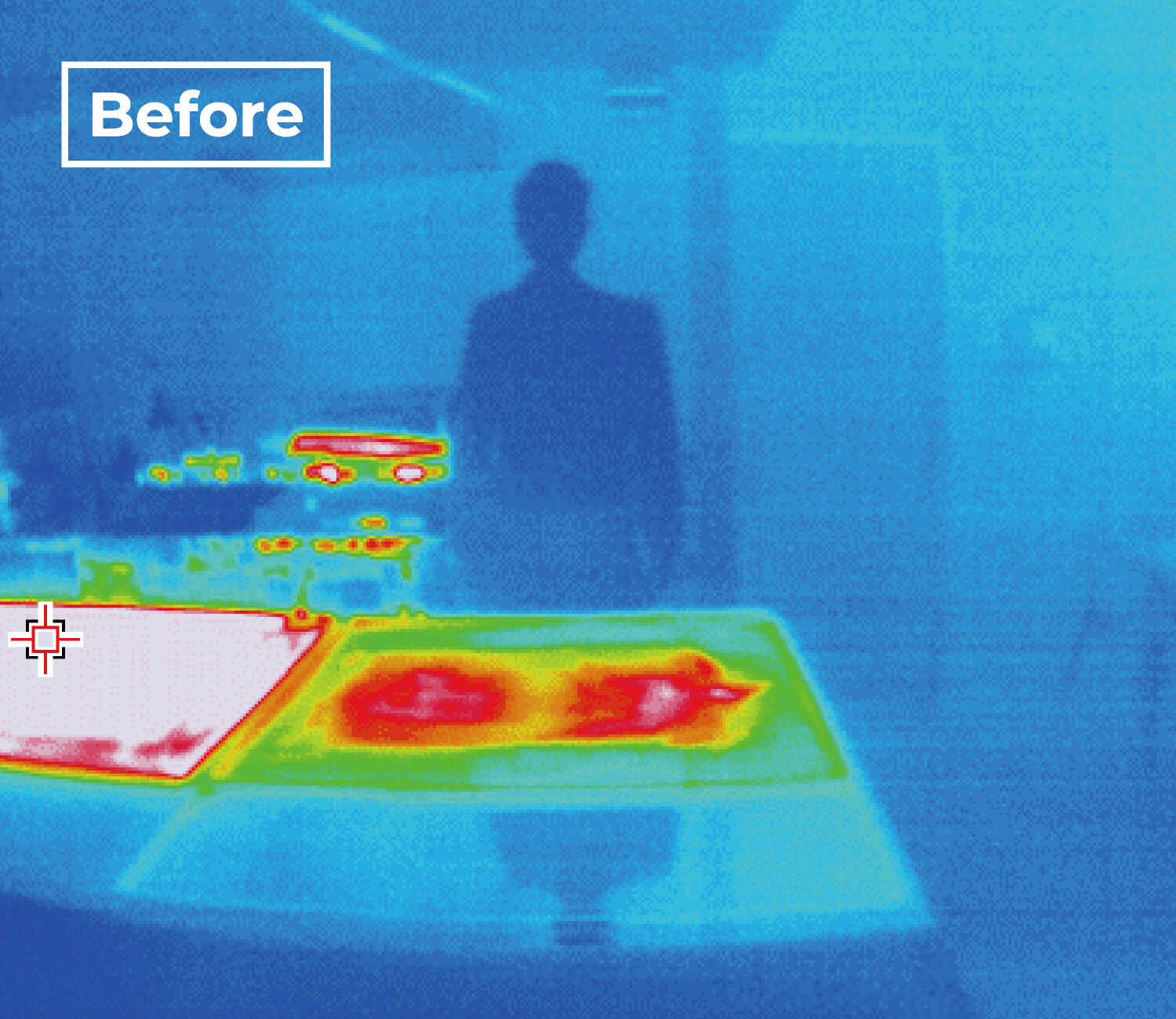

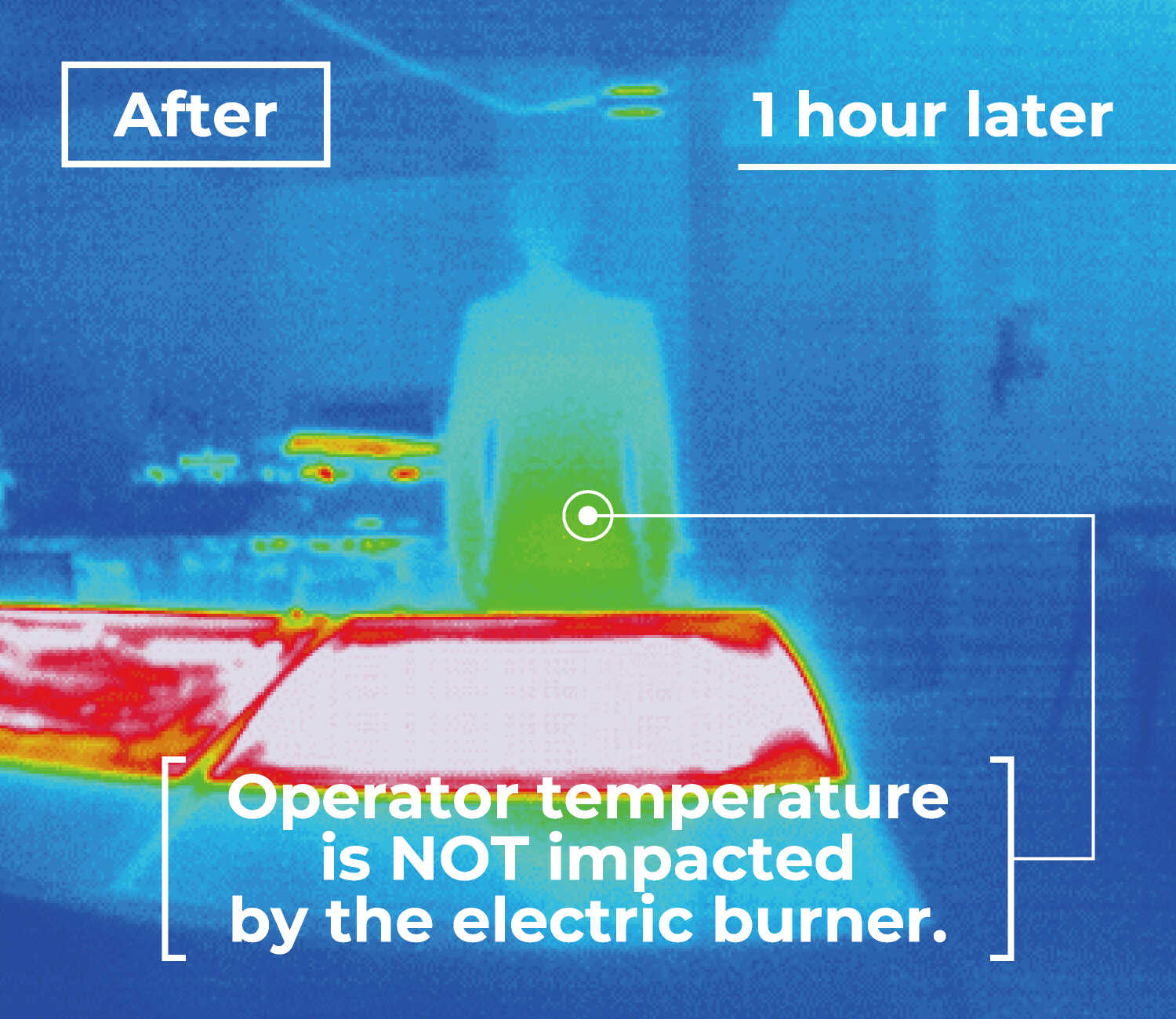

The radiant heat emitted from a hot teppan can have unintended consequences.

The ambient temperature of the cooking area can significantly increase. The temperature of the dining area can also increase if additional air conditioning is not used. The body temperature of the teppan operator can also increase significantly.

Thermographic images were taken of 2 scenarios.

The electric Carbon Lamp Heating system has an easier digital temp control system and is able to mitigate temp increases within the immediate vicinity of the teppan and, over time, the entire room. This result would lead to the following considerations:

To export Teppan equipment, it is extremely important to meet the standard safety design regulations of the country it’s going to.